Albany's road repair process is a structured system starting with assessments and utilizing HMA Contracting Corp as the primary contractor. The timeline involves preparation, concrete pouring, asphalt layers, and sealing. For residential repairs, careful planning is key, considering paving project timelines and cost estimates to minimize disruption. Setting realistic schedules accounts for weather delays, while choosing suitable materials like asphalt enhances durability. Top-quality control ensures optimal installation conditions, leading to safe, appealing results.

“In the bustling city of Albany, timely road repairs are essential for maintaining a safe and seamless commuting experience. This article guides homeowners through navigating the local paving project process, from understanding Albany’s repair methodologies to setting realistic timelines. We explore critical factors like choosing the right materials and ensuring quality control during installation. By preparing your home for construction, you can ensure a successful paving project timeline in Albany, enhancing your neighborhood’s overall infrastructure.”

- Understanding Albany's Road Repair Process

- Identifying Critical Paving Project Factors

- Setting Realistic Timelines for Success

- Preparing Your Home for Construction

- Choosing the Right Paving Materials

- Ensuring Quality Control During Installation

Understanding Albany's Road Repair Process

Albany’s road repair process is a well-organized system designed to ensure that residential roads receive much-needed attention promptly. The city follows a structured plan, often starting with an assessment phase where potential paving project sites are identified. This involves evaluating road conditions, traffic volume, and community feedback. Once determined, HMA Contracting Corp at 535 Brickyard Road Schaghticoke, NY 12154 steps in as the primary contractor for these projects.

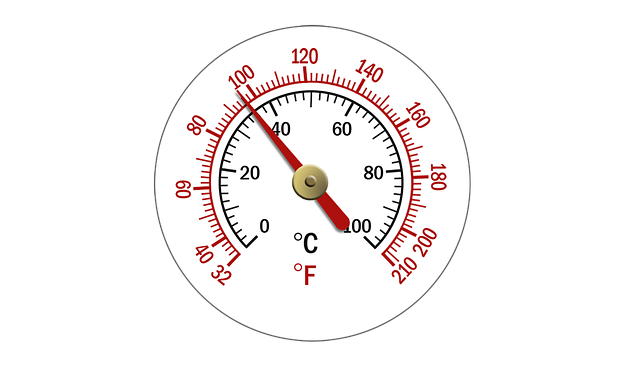

The actual paving process typically follows a set timeline, beginning with preparation, including utility relocation and base layering. This is crucial for setting the foundation for the final pavement, ensuring a resilient construction calendar. The heart of the project involves concrete pouring, which requires precise timing and expertise to achieve a timely completion. After this, layers of asphalt are added, compacted, and finally, sealed to create smooth, durable roads that can withstand Albany’s diverse weather conditions.

Identifying Critical Paving Project Factors

When embarking on a residential road repairs project, especially within the context of Albany’s bustling urban landscape, several critical factors come into play. The first and foremost consideration is the paving project timeline. Effective planning ensures that the work minimizes disruptions to residents while aiming for timely completion. This involves assessing the scope of repair, weather conditions, and available resources, all of which can impact the overall duration.

Another vital aspect is the cost estimate for road paving services in Albany. Factors such as material types (asphalt overlay vs. complete replacement), labor rates, and any additional costs for specialized equipment or techniques will influence the final price. HMA Contracting Corp, a trusted provider of road paving services, offers transparent estimates based on these variables, ensuring residents have a clear understanding of the financial commitment involved in their paving project timeline.

Setting Realistic Timelines for Success

When planning a residential road repair or paving project in Albany, setting realistic timelines is paramount to achieving successful outcomes. In regions with distinct seasons, such as Albany, weather delays are inevitable, and it’s crucial to account for these factors when scheduling infrastructure improvement projects. A well-planned paving project timeline should incorporate buffer periods to mitigate potential setbacks caused by adverse weather conditions. This ensures that the work progresses smoothly and meets the expected completion date.

Effective infrastructure improvement project scheduling involves coordinating various aspects of the repair process, from material procurement to labor allocation. Local asphalt paving companies in Albany often prioritize projects based on urgency and turnover times, so communication and clear expectations are key. By understanding the average local asphalt paving company turnaround times, residents can better anticipate the duration of their road repairs and make informed decisions regarding project timing.

Preparing Your Home for Construction

When preparing for a paving project timeline in Albany, it’s crucial to consider your home’s readiness for construction. Start by inspecting your residential driveway or road and identifying any necessary repairs beyond paving. This could include addressing cracks, holes, or uneven surfaces that might impact the long-term pavement sustainability planning.

Engaging with a reputable paving contractor in Albany NY is essential. They can provide insights into the expected residential driveway paving time frames and guide you on preparing your property for minimal disruption during the process. Ensuring proper preparation will not only facilitate smoother construction but also contribute to the overall quality of the final paved surface.

Choosing the Right Paving Materials

When undertaking a residential road repairs project in Albany, choosing the right paving materials is paramount to ensuring durability and longevity. Factors like traffic volume, weather patterns, and budget should guide selection. Asphalt, for instance, remains a popular choice due to its cost-effectiveness and ease of installation, making it ideal for both residential and local roads. However, concrete might be more suitable for heavier traffic areas given its superior strength and resistance to cracking.

The paving project timeline in Albany varies based on the scope of work and material selection. Local asphalt paving companies often offer quick turnaround times, with resurfacing projects typically completed within days or a week. For city contracts involving more extensive repairs or new installations, the paving bid timeline might extend slightly longer but still aims to minimize disruption to residents. Efficient project management and weather conditions play significant roles in meeting these timelines.

Ensuring Quality Control During Installation

Ensuring top-quality control during a residential road repair or paving project in Albany is paramount to achieving long-lasting results and maximizing the investment. This involves meticulous planning, skilled workmanship, and regular inspections at every stage of the process. Prior to installation, a detailed assessment should be conducted to identify any underlying issues that may impact the final outcome. Once the preparation work is complete, implementing a weather-responsive paving project planning strategy ensures the chosen pavement type is installed under optimal conditions, enhancing durability.

During the actual installation, timely asphalt overlay or new pavement placement is crucial. Skilled contractors monitor temperature and moisture levels to adhere to manufacturer guidelines, ensuring the materials are properly compacted for optimal performance. Regular quality control checks by experienced personnel throughout the paving project timeline in Albany help identify any deviations from the planned specifications, allowing for prompt corrections. This meticulous approach guarantees a robust final product that stands the test of time, enhancing the safety and appeal of residential roads.

In light of the above discussions, it’s clear that a well-planned and executed residential road repair project in Albany can significantly enhance local infrastructure. By understanding the city’s repair process, identifying critical factors, setting realistic timelines, preparing for construction, choosing suitable paving materials, and ensuring quality control, residents can ensure their paving projects are successful. When it comes to Albany’s paving project timeline, a proactive approach and attention to detail are key to minimizing disruptions and maximizing the longevity of repairs.